Environmental Resistance Testing for Surface Mount Components

Environmental Resistance Testing for Surface Mount Components A Crucial Service for Businesses

In todays fast-paced and highly competitive electronics industry, manufacturers are constantly seeking innovative ways to ensure the reliability and performance of their products. One crucial service that can make a significant difference in product success is Environmental Resistance Testing for Surface Mount Components (SMT) offered by Eurolab.

What is Environmental Resistance Testing?

Environmental Resistance Testing, also known as environmental testing or accelerated stress testing, simulates various environmental conditions to evaluate the performance and reliability of SMT components. This laboratory service evaluates a components ability to withstand extreme temperatures, humidity levels, vibration, shock, and other environmental stresses that can impact its functionality.

Why is Environmental Resistance Testing Essential?

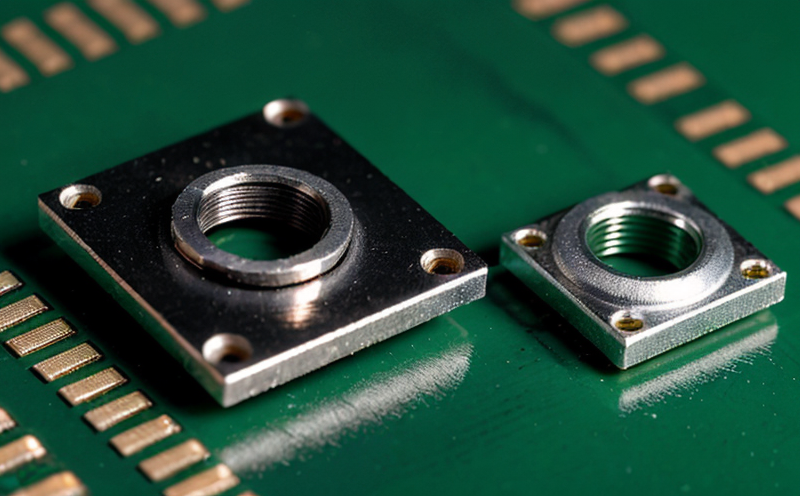

Environmental factors play a significant role in determining the lifespan and reliability of electronic components. The increased use of miniaturized SMT components has made them more susceptible to various environmental stressors, including temperature fluctuations, humidity changes, and mechanical shocks. Without thorough testing, manufacturers risk releasing products that may fail prematurely or exhibit reduced performance.

Advantages of Environmental Resistance Testing for Surface Mount Components

Eurolabs Environmental Resistance Testing service offers numerous benefits to businesses

Improved Product Reliability By simulating real-world environmental conditions, Eurolab helps ensure that SMT components can withstand the rigors of production, transportation, and storage.

Enhanced Durability Our testing services identify potential weaknesses in components, enabling manufacturers to select more robust alternatives or design improvements.

Reduced Warranty Claims With increased component reliability, businesses can minimize warranty claims and associated costs.

Increased Customer Satisfaction By ensuring products meet or exceed customer expectations, companies can foster loyalty and expand their market share.

Compliance with Industry Standards Eurolabs testing services align with relevant industry standards (e.g., IEC 60068-2), facilitating compliance and reducing the risk of costly rework.

Key Benefits of Environmental Resistance Testing

Here are some essential benefits of using Eurolabs Environmental Resistance Testing service for SMT components

Temperature Extremes Evaluate component performance under various temperature conditions, including high-temperature storage and low-temperature operation.

Humidity Exposure Test components ability to withstand humidity levels that can lead to corrosion or reliability issues.

Vibration and Shock Resistance Assess a components resilience to mechanical shocks and vibrations that can occur during transportation or use.

Moisture Sensitivity Identify components sensitive to moisture exposure, enabling selection of more suitable alternatives.

Comprehensive Testing Capabilities

Eurolab offers a range of testing methods to simulate various environmental conditions

Temperature Cycling

Thermal Shock

Humidity Chamber Testing

Vibration and Shock Testing

Moisture Sensitivity Testing

Corrosion Resistance Testing

QA Section Addressing Common Concerns

Q What is the purpose of Environmental Resistance Testing?

A The primary goal is to evaluate SMT components ability to withstand various environmental stressors, ensuring reliability and performance.

Q Which industries benefit from Environmental Resistance Testing?

A All electronics manufacturers can benefit from this service, including those in aerospace, automotive, medical devices, consumer electronics, and industrial equipment.

Q What are the typical testing environments simulated?

A Eurolabs services include simulation of temperature extremes, humidity levels, vibration, shock, and moisture sensitivity.

Q How do I choose the right components for my product?

A Our experts can help you select components with improved reliability by analyzing test results and providing recommendations based on your specific needs.

Conclusion

Environmental Resistance Testing for SMT components is an essential service that enables businesses to ensure their products meet or exceed customer expectations. By partnering with Eurolab, manufacturers can gain confidence in the performance and reliability of their products. Our comprehensive testing services align with industry standards, ensuring compliance and reducing costs associated with rework and warranty claims.

At Eurolab, we are committed to helping our clients succeed by providing expert laboratory services that meet their unique needs. If youre ready to take your products reliability to the next level, contact us today to learn more about our Environmental Resistance Testing service for SMT components.