Adhesion Testing for Surface Mount LEDs and Chips

The Critical Importance of Adhesion Testing for Surface Mount LEDs and Chips Ensuring Reliability and Efficiency in Electronics Manufacturing

In the highly competitive world of electronics manufacturing, ensuring the reliability and efficiency of components is paramount to success. One critical aspect that often goes unnoticed is the adhesion between surface mount LEDs (SMT LEDs) and chips, which can have a significant impact on product performance and lifespan. Adhesion testing for SMT LEDs and chips is an essential laboratory service that helps manufacturers identify potential issues before they become major problems.

At Eurolab, our team of expert technicians specializes in providing comprehensive adhesion testing services for surface mount LEDs and chips. In this article, we will delve into the importance of adhesion testing, its advantages, and key benefits, as well as answer frequently asked questions to help you understand why this service is a must-have for your business.

What is Adhesion Testing for Surface Mount LEDs and Chips?

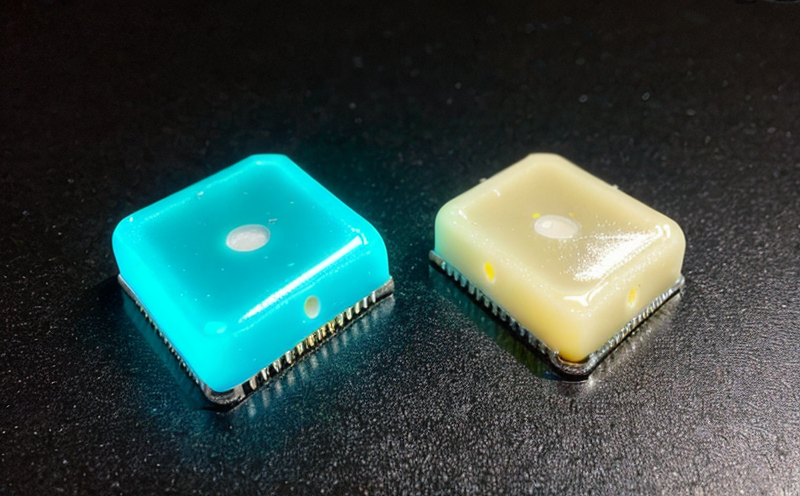

Adhesion testing involves evaluating the bond strength between surface mount LEDs or chips and the underlying substrate or circuit board. This includes assessing the effectiveness of the adhesive used, as well as any issues that may arise from defects in the manufacturing process. By conducting adhesion tests, manufacturers can identify potential problems that could lead to component failure, electrical shorts, or other issues that compromise product performance.

Advantages of Adhesion Testing for Surface Mount LEDs and Chips

The benefits of adhesion testing for SMT LEDs and chips are numerous, including

Improved Product Reliability By identifying and addressing adhesion-related issues early on, manufacturers can significantly reduce the risk of component failure and associated downtime.

Increased Efficiency Efficient manufacturing processes rely on reliable components. Adhesion testing ensures that products meet quality standards, reducing the need for costly rework or replacement.

Enhanced Customer Satisfaction When products perform as expected, customers are more likely to be satisfied with their purchases. Adhesion testing contributes to overall product excellence and brand reputation.

Reduced Warranty Claims By identifying adhesion-related issues before shipping, manufacturers can minimize warranty claims and associated costs.

Key Benefits of Adhesion Testing for Surface Mount LEDs and Chips

Here are the key benefits of our adhesion testing services at Eurolab

Comprehensive Analysis Our team conducts thorough examinations to identify any potential issues with adhesive bonding, including defects in manufacturing processes.

Quick Turnaround Times We understand that time is of the essence in electronics manufacturing. Our fast turnaround times ensure that you can quickly address any adhesion-related issues.

Accurate Results Our expert technicians use state-of-the-art equipment and techniques to provide accurate results, giving you confidence in your products reliability.

Customized Testing Packages We offer tailored testing packages to meet the specific needs of your business, whether its a small batch or high-volume production.

Frequently Asked Questions

Weve compiled a list of frequently asked questions to help you better understand our adhesion testing services

Q What types of surface mount LEDs and chips can be tested?

A Our team can test various types of SMT LEDs and chips, including QFN (Quad Flat No-leads), TDFN (Thin Dual Flat No-leads), SOIC (Small Outline Integrated Circuit), and more.

Q How do I prepare my components for testing?

A Simply send us your components in their original packaging or encased as received from the manufacturer. Our technicians will handle all necessary preparation and testing procedures.

Q What are the typical turnaround times for adhesion testing services?

A Turnaround times vary depending on the complexity of the test, but we typically complete our services within 24-48 hours.

Q Can I request customized testing packages or protocols?

A Yes! Our team works closely with clients to develop tailored testing packages that meet specific business needs and requirements.

Conclusion

In todays fast-paced electronics manufacturing landscape, ensuring the reliability and efficiency of components is crucial for success. Adhesion testing for surface mount LEDs and chips plays a critical role in identifying potential issues before they become major problems. At Eurolab, our team is dedicated to providing comprehensive adhesion testing services that help manufacturers like you improve product reliability, increase efficiency, enhance customer satisfaction, and reduce warranty claims.

Dont let adhesion-related issues compromise your products performance or reputation. Trust Eurolabs expert technicians to provide accurate results and help you achieve excellence in electronics manufacturing. Contact us today to learn more about our adhesion testing services and how we can support your business needs.